Pixel Shift 16-shots versus Stitching

Revealing real-world photographic examples about the nature of Pixel Shift you won’t find anywhere else. How useful is Pixel Shift? Does it actually increase resolution?

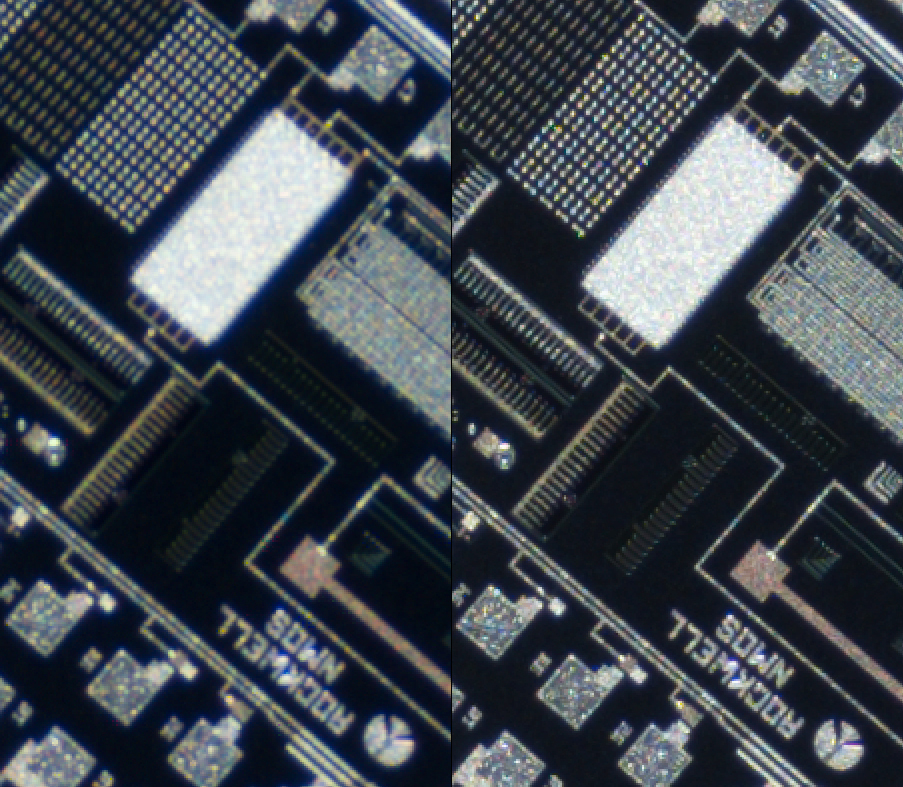

One is a single shot, one is pixel shifted 16-shots, can you guess which is which? It’s not quite what you might expect…

Taming Obdurate Orchids

A glimpse into overcoming some of the challenges of making pictures of orchids, the Fujifilm GFX 100S and a bonus bit about sensor crookedness

Dendrobium Airey Peach, 2023. Photograph notes: Sony a7R II with SMC Pentax-A 645 120mm F/4 Macro, natural daylight illumination, F11, 51 focus-bracketed exposures, raws processed in RawTherapee using custom made camera profile, blended in Helicon Focus.

Wrestling with Printer-Induced Roller Marks on Paper

Problems with the mechanics of how printers handle fine quality paper for printing

Canson BKF Rives 310gsm paper loaded into Canon iPF8400 printer, showing pinch roller marks. This is equivalent to the worst-case scenario with my first iPF8400 if the paper was passed under the rollers about 5 times or more. For some reason, my documentation from seven years ago was lost, so I had to re-create equivalent roller pressure on the paper. Illumination is indirect sunlight from the balcony to the right, somewhat diffused but sufficient to notice the problem. The dents running vertically down the paper correspond perfectly to the roller positions. Note the grey lever mechanism in the lower right, which the user manually operates to raise and lower the pinch rollers (the little grey cylinders about 13mm wide running horizontally on the far side of the visible portion of the paper).

This is what the problem looks like, is totally unacceptable and one way or another, I had to make it go away.

Your Cameras and Lenses are Crooked and How to Adjust Them

Plus a bunch of tidbits about some of the challenges in making astro-landscape photographs

Silver River Shimmers, 2017

Photograph notes: This is a composite of 4 vertical frames stitched for the sky and another 4 vertical frames stitched for the land for a total of 93.8 million pixels, using a Sony a7R II at ISO 800 and Canon EF 35mm f/1.4L II USM. Each of the sky frames was stacked and averaged from nine 32-second exposures at f/2.8. The land frames were stacked and averaged from four 32-second exposures at f/4 made 23 mins later at predawn to avoid shadows from the sun. 52 exposures were used in all. The sky exposures were tracked with a Sky-Watcher Star Adventurer.

Anti-reflection Picture Framing Glass – Part 2

On invisible things, and those that claim to be

Just because you don’t see something doesn’t mean it isn’t there. Some of the most wonderful things in the world are invisible. Trusting in invisible things makes them more powerful and wondrous. ― Kelly Barnhill, The Girl Who Drank the Moon

The Framing Glass—or rather the lack of it

Thoughts and evaluations of anti-reflection picture framing glass

Tell people there’s an invisible man in the sky who created the universe, and the vast majority will believe you. Tell them the paint is wet, and they have to touch it to be sure. ―

Artglass specifier frame comparing regular glass to anti-reflection glass.