The Framing Glass—or rather the lack of it

Thoughts and evaluations of anti-reflection picture framing glass

Tell people there’s an invisible man in the sky who created the universe, and the vast majority will believe you. Tell them the paint is wet, and they have to touch it to be sure. ―

Artglass specifier frame comparing regular glass to anti-reflection glass.

This article is targeted mainly at artists, custom framers and conservators who are particular about the way artwork is presented, preserved and protected. If you are squeezed for time, skip to the evaluations here, or the conclusion here. But if you are new to all this I suggest reading from the beginning.

Introduction

As a maker of finely crafted prints, I want them to look as good as possible, so it is rather bothersome when we cannot see them as well once they are framed behind glass, due to its obtrusive reflections and greenish tint. Framing without glazing is out of the question for fine prints in the interest of long-term preservation. It shields the art from physical damage, atmospheric pollutants and to varying extents, degradation from ultraviolet (UV) light. What we need then is highly transparent, anti-reflective glass.

Uncoated “regular” soda lime glass (and clear acrylic) reflects about 8% of light in total (4% off each side). The glass itself absorbs another ~2% or more of light. But the absorption is not uniform across the visible spectrum. Iron oxides naturally present in silica, the main ingredient of soda lime glass, is responsible for its green tint. This is most visible when looking at the edges of float glass. Low iron glass is manufactured from silica with very low iron content. This makes the glass almost completely neutral in colour and light absorption is reduced to about 0.5% or less. Clear acrylic has the advantage of having absolutely no colour tint and absorbing virtually no light at all.

To increase the transparency of glass still further, we need something else to reduce surface reflections—anti-reflection (AR) coatings.

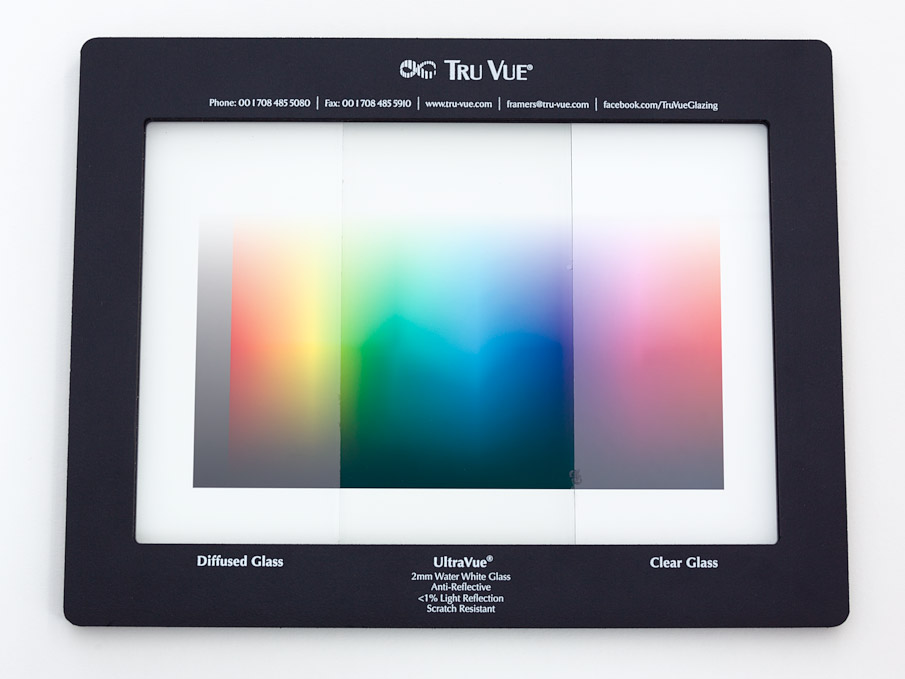

Initially developed in 1935 for optical lenses, AR coatings are widely used today in many applications. They are very effective when applied in multiple thin layers of metal oxides, by sputter deposition (what almost everyone does today) or by dipping (Sol-gel process used by Schott). The coatings reduce surface reflections by taking advantage of the phenomenon of destructive interference to cancel out the reflecting rays of light, therefore increasing the amount of transmitted light. A simple explanation is the light reflected from the surface of the coating will meet the light reflected from the surface of the glass and be exactly out of phase, cancelling each other. And since the law of conservation of energy states that energy cannot be destroyed (or created), the reflected light energy that cancelled out must, therefore, be transmitted through the glass, and so increasing the transmitted light and making the glass seem more transparent. The most effective coatings can reduce reflections to less than 1% in total. The difference is tremendous when compared to regular glass, as seen in these specifier frames—there appears to be nothing in the centre of the frame. These comparison samples get a lot of finger poking from everyone I show them to, really neat stuff.

Tru Vue specifier frame comparing regular and etched glass to anti-reflection glass

Among the companies producing and selling AR coated picture framing glazing, Tru Vue is perhaps the best-known among framers. Notably, they are currently the only company that makes anti-reflective coated acrylic. Groglass is an exciting newcomer with a strong focus on picture framing glazing. They make the Artglass line of AR glass and promises an AR acrylic sometime in the future. I am excited to see how it compares to Tru Vue’s Optium Museum Acrylic. At the point of writing, I have received glass samples from Tru Vue and Groglass, via their marketing programs, which anyone can request free samples from. Other AR glass products of interest are Schott Mirogard, Guardian Brilliance, Flabeg Picture Glass, HY-TECH-GLASS LUXAR and Saint Gobain SSG VISION-LITE. Some of these glasses are re-branded and sold under different names. Some have come and gone like Claryl. I have not managed to procure samples of these glasses yet and will update this article when I do.

On Transmission, Reflection and Coatings

To evaluate the performance of these glasses, I studied at them side-by-side under different lighting conditions, tilting and peering at different angles. I found that placing the glasses over black light trap flocking best reveals subtle visual differences in reflection colour and brightness, and the transmission performance of the glass could be easily seen by the density and colour shift of the black flocking material behind glass. I also measured some samples using a PerkinElmer LAMBDA 950 spectrophotometer, courtesy of Nanyang Technological University, School of Physical and Mathematical Sciences, Division of Physics and Applied Physics. The measuring set up is very high end (UV/Vis resolution ≤ 0.05 nm, wavelength accuracy ± 0.080 nm, wavelength reproducibility ≤ 0.020 nm) and well maintained. The spectral transmission measurements were made with the light source perpendicular to the glass, without an integrating sphere. I was unable to perform more measurements given the limited time I was allowed to use the equipment. Thereafter, informed by the measurement data, I realised that human vision is remarkably sensitive to subtle differences in low-level brightness and one can easily make out a 0.5% difference between reflection brightness, meaning visual comparative evaluations based off a known reference should be quite reliable.

PerkinElmer LAMBDA 950 Spectrophotometer, in situ

When regular glass reflects light, the reflection colour is essentially neutral. When AR coated glass reflects light, it is always tinted. What colour tint depends on how the coating was engineered but is usually greenish, bluish or pink. The colour may be very intense or rather faint. And the reflection colour changes depending on incident light angles and viewing angles. Some coatings simply shift to a neutral reflection colour at more oblique angles while others shift to a longer wavelength of colour first before shifting to neutral. In gallery lighting situations, the spotlights are often at about 45 degrees to artwork, and coatings that shift to a pink-reddish colour thus transmit more green-blue light, resulting in a cyan tint in the artwork, undoing to some degree the investment in using low-iron float as the base substrate. This pernicious issue turned out to be more serious in the real-world than I previously thought, though likely to go by unnoticed to many. The shifting phenomenon is well explained on Wikipedia, emphasis mine:

If the coated optic is used at non-normal incidence (that is, with light rays not perpendicular to the surface), the anti-reflection capabilities are degraded somewhat. This occurs because the phase accumulated in the layer relative to the phase of the light immediately reflected decreases as the angle increases from normal. This is counterintuitive, since the ray experiences a greater total phase shift in the layer than for normal incidence. This paradox is resolved by noting that the ray will exit the layer spatially offset from where it entered, and will interfere with reflections from incoming rays that had to travel further (thus accumulating more phase of their own) to arrive at the interface. The net effect is that the relative phase is actually reduced, shifting the coating, such that the anti-reflection band of the coating tends to move to shorter wavelengths as the optic is tilted. Non-normal incidence angles also usually cause the reflection to be polarization dependent.

AR coatings for picture framing glass are designed to work best when looking straight on, perpendicularly, the normal way people look at framed artwork. Their ability to reduce reflections is greatly diminished when looking at them diagonally. At viewing angles past 45 – 60 degrees, the AR effect is totally eliminated but this is of much less concern because of the awkward viewing angle. Most lighting situations in reality is somewhat diffused, so there usually is some low level of reflections present. We shall see later that among the glasses that promise 99% transmission, not all look as clear in real world situations.

AR coatings differ in reflection brightness, reflection colour, reflection colour intensity, reflection colour at an angle, how well light is transmitted, durability and ease of cleaning. I must caution against placing full trust in manufacturer stated specifications. Some products completely fail to meet the published specifications. Buyer beware! Manufacturing variations (especially coating inconsistencies) will always be present and companies have made changes to their coatings over time. It pays to know the coating characteristics your favourite glass, so you can tell if something is wrong just by eyeballing it. That said, when all the stars align, the best AR coatings are truly remarkable and I now cannot live with anything else for my framed prints.

Photographic Examples

I have two photo series of side-by-side comparisons of four AR glasses, Tru Vue Ultravue. Tru Vue Museum Glass, Groglass Artglass UV70 (previously Artglass WW), and Groglass Artglass UV92 (previously Artglass WW UV). To reduce page load times I have placed them in separate webpages from this main article. I photographed the glasses over prints made on Epson Hot Press Natural paper, which does not contain fluorescing dyes, with a Canon 5D II camera under natural daylight illumination (cloudy skies). The raw image files were converted in Adobe Camera Raw using a custom daylight camera profile, with minimal adjustments to correct for white balance and exposure. I include a reference image of the bare print also.

Despite my best efforts to portray the differences as I saw them, some of the nuances were lost in the photo capture process, and more still if you are looking at them on a low quality or uncalibrated display. In some examples, the diffused lighting reveals significant differences in the way the glasses transmit or reflect light. Nothing beats experiencing them with your own eyes. The next time you go to your framers, ask them for samples or examples of these glasses if they stock them.

Here is the link to the image series of the glasses over a printed black synthetic target, with additional images showing the reflection color change at approximately 60 degrees reflection and 30 degrees reflection.

Here is the link to the image series of the glasses over a printed grayscale image.

I suggest looking at the comparison images in at least the first link, before going on to read my evaluations of the glass so you get to have a ‘first impression’ of your own.

Evaluations

Regular Soda Lime Glass

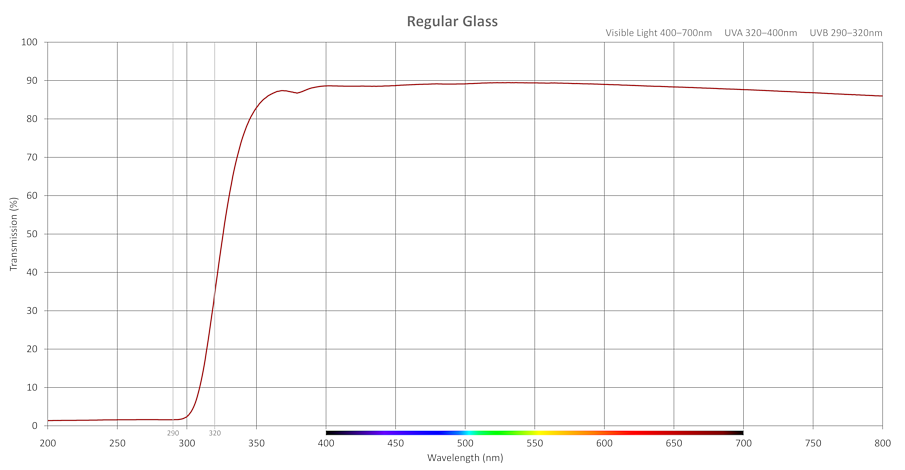

To form a basis for comparison, this is the spectral transmission of regular soda lime float glass (sample measured at 1.9mm thickness), its slight green tint evidenced in slight rise of the transmission curve at 500‒550nm, falling away gently towards the ends of the visible spectrum. For those unaccustomed to seeing such representations, I placed a strip of the visible light spectra at the bottom of the graph which approximates the color we see at the corresponding numerical wavelength. UVA light is from 320‒400nm, and UVB light is from 290‒320nm. All is as expected from the uncoated glass―about 89% transmission overall. Regular glass transmits almost no UVB light (higher frequencies than that are filtered out by the Earth’s atmosphere and are not of concern) and about 50% of UVA light.

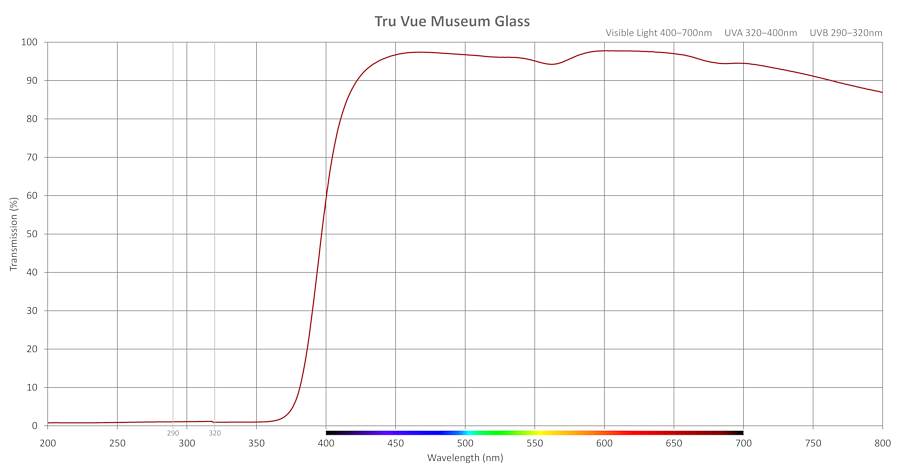

Tru Vue Museum Glass is the world-famous old standby for UV filtering AR glass. It is a 99% UV absorbing glass with AR coating. The base substrate is regular soda lime glass in 2.5mm thickness (sample measured 2.1mm). The UV absorbing coating is rolled on one side only, then the glass is AR coated by magnetron sputtering on both sides. The UV coated side is more fragile and should be framed facing inwards to prevent scratching. Because it is an absorptive type coating as opposed to interference-based, its 99% UV blocking rating (from 380nm and below) is effective at all angles of incident light entry.

Of these four AR coated glasses, Tru Vue Museum Glass transmits the least amount of light and in the least uniform manner. The overall tint is somewhat orange-brown, the maximum transmission peaking at 590‒650nm. A sort of bonus side effect of having a UV absorbing coating, the orangey coating color completely neutralizes the green tint of the glass. Reflections are not tamed as well compared to UltraVue and Artglass WW. The glass tends to reduce black density and contrast of darker colors a little more than the others.

Wavy texture of Museum Glass visible in specular reflection

The AR coating color of Museum Glass is a muted greenish-cyan when looking straight on. The color shifts to magenta at oblique reflection angles ( ~30‒45 degrees). Color shifts of this nature is highly undesirable in picture framing glass. In addition, the UV coating has a low frequency rippling effect that is easily observed when the glass catches some specular reflections. When illuminated by directional lighting, the ripples in the coating cast a pronounced pattern of shadows which I find to be extremely disagreeable. The further the glass is from the artwork, the more visible the shadows. A spacing equal to a 4 ply mat is enough to make shadows visible, let alone the depths introduced by shadow box framing. This is rather disappointing from a product held in high regard by museums and conservation framers.

Wavy texture of Museum Glass results in corresponding rippling shadow pattern

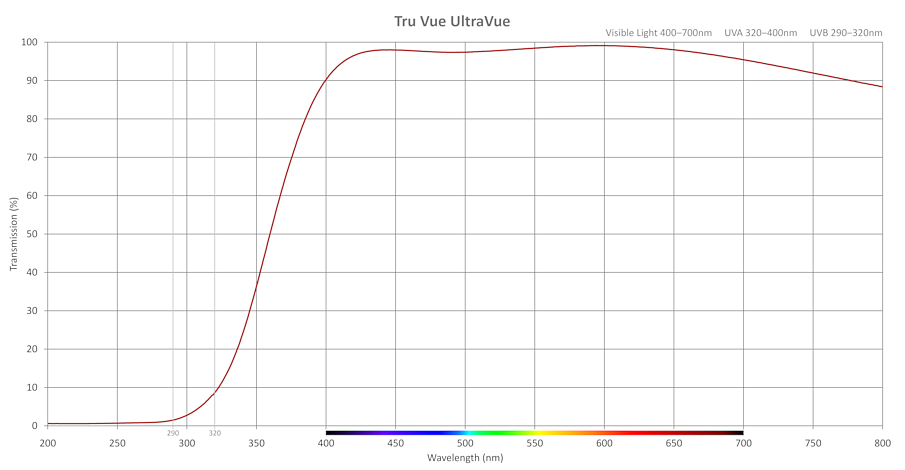

Tru Vue UltraVue UV70

Tru Vue UltraVue UV70 was launched relatively recently in response to the introduction of Groglass Artglass WW. Both use low iron float glass of 2mm thickness (sample measured 1.7‒1.8mm) which allow for even higher light transmissions than regular glass. UltraVue and Artglass WW are specified to filter 70% of UV light from 280‒380nm. The spectral curves indicate that UltraVue blocks a tad less UV light, but this detail is inconsequential. Both sacrifice maximum UV blocking by design for greater transmission of visible light. For papers that contain optical brighteners, these glasses will allow most of the fluorescing effect to remain visible as long as the viewing light contains some amount of UV.

When illuminated straight on with a gallery spotlight (directional lighting), UltraVue has a very slight orange tint, evidenced in the spectral transmission graph showing a slight rise from 550‒650nm. When light strikes it at shallower angles (like in most normal situations where the light source is hanging off the ceiling) or under diffused lighting, the glass has a cyanish tint, owing to its coating color shift problem. Reflections are less bright than Museum Glass, but worse than Artglass WW. There is an obvious cyan tint to the artwork and visibly reduces black density in prints.

Like Museum Glass, the coating color shifts objectionably to magenta at more oblique reflection angles. The magenta-shift color intensity varies in my samples, as expected. In almost every case, I was able to observe the cyan tint of UltraVue, over paper white, neutral colors and black flocking. You can see this in my photographic examples. For a printmaker who has spent a great deal of time to craft the color of my prints, this color tinting is most objectionable.

UltraVue Transmission and Reflection color is greenish-cyan and magenta

I photographed my sample of UltraVue illuminated by a gallery spotlight striking the glass at an angle to reveal the transmission/reflection band shift phenomenon. You can see in the image above the transmitted light (cast on the left side) has a cyan tint and the reflected light is pinkish.

And here is a video showing the same phenomenon as I play with tilting the glass. While it is rather fun to watch this dichroic phenomenon, I am not pleased to let anything mess about with the visual effect of my prints!

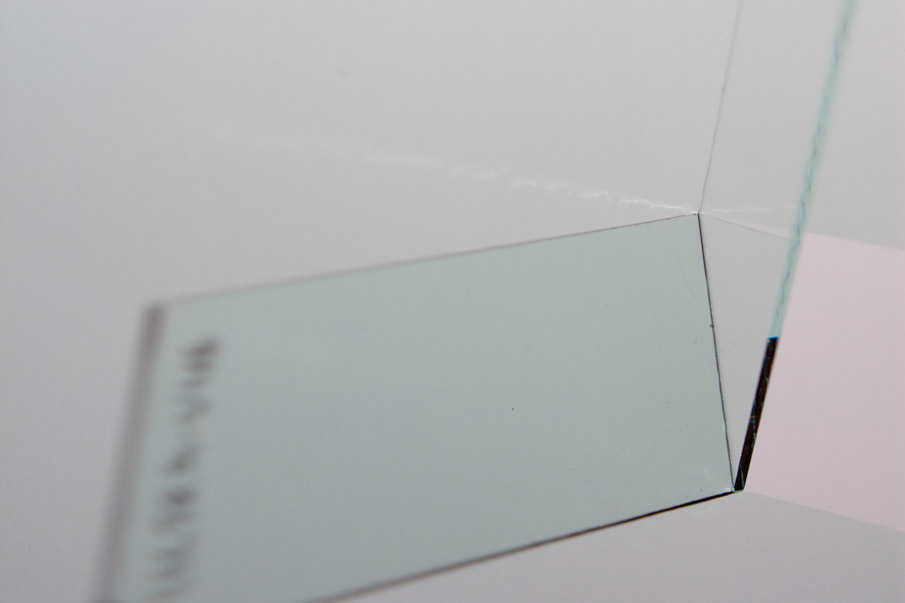

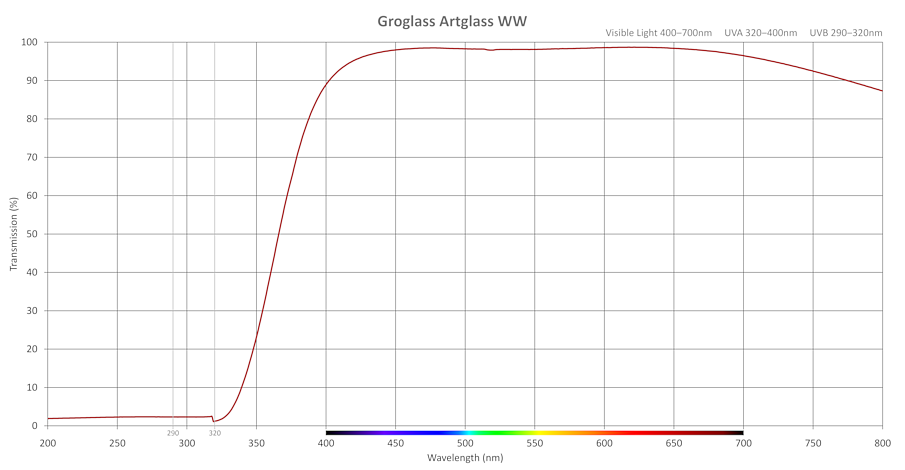

Groglass Artglass AR 70 (previously Artglass WW)

Groglass Artglass AR 70 (previously WW which stands for Water White) is the direct competitor to UltraVue and has almost identical manufacturer specifications. It has the highest visual and measured transmission of these four glasses. Light is transmitted very uniformly across the visible spectrum, only falling away slightly at the UV and infrared ends. It has such minimal color shifting it was mostly impossible to detect by eye.

The coating reflection color of Artglass AR 70 is a muted green, more yellowish than Museum Glass. My other sample has a reflection color that is even more yellow-green. Despite the coating variance the optical performance of my samples and actual production pieces are just as high. The coating color gradually changes to neutral at more oblique incident light angles without shifting to opposing hues (pink) like UltraVue and Museum Glass. It reflects the least light of these four glasses. Artglass AR 70 is wonderfully transparent. Grayscale hues are almost perfectly preserved and black densities appear almost completely unchanged, maintaining the brilliance and contrast of the original. Artglass AR 70 sets the standard for all other glasses for remarkably low reflections.

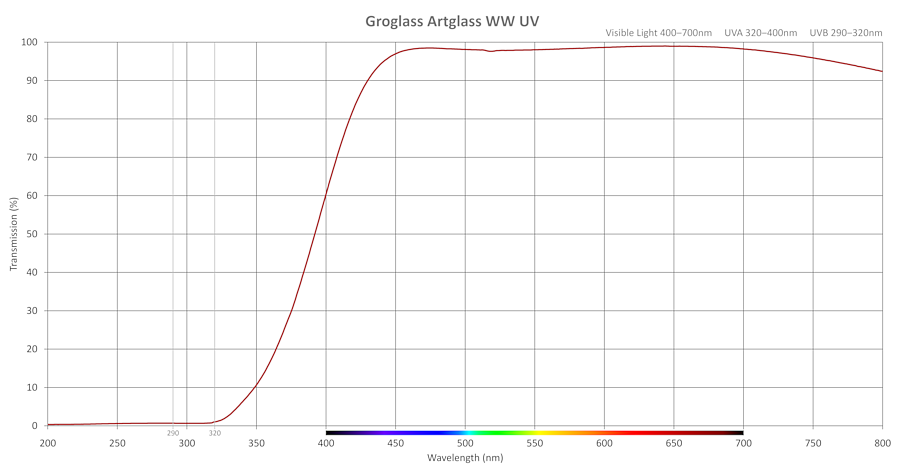

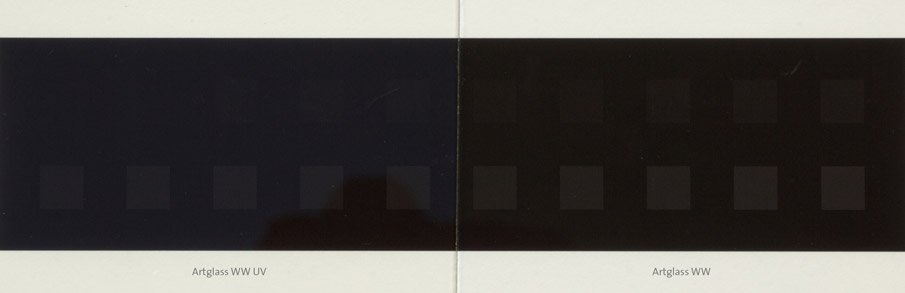

Groglass Artglass AR 92 (previously WW UV)

Groglass Artglass AR 92 is similar to Artglass AR 70 but with a different coating, rated to block a higher amount of UV light. It’s specified to be >90% UV blocking. The UV coating is an interference type instead of absorbing like Museum Glass, so its UV blocking rating is only good for light hitting the glass at zero degrees incident (perpendicularly). As with all reflective type coatings, its potency is gradually lessened at more oblique angles of light entry. Past 45 degrees incident, interference type coatings are totally ineffective, as good as no coating at all. The intent with this product is to maintain relatively high UV filtration without sacrificing too much transparency, prioritizing the clarity over maximum UV protection. The glass has a slight yellowish tint from attenuating visible light at about 450nm. The cutoff band is much wider than Museum Glass, about 130nm vs 60nm, another limitation of interference type UV blocking coatings.

Artglass AR 92 has very high transmission of visible light, a fraction of a percent less than UltraVue and Artglass AR 70. In side by side comparisons against Museum Glass, the transmission difference is obvious. Blacks behind Artglass AR 92 look much better with perhaps slightly more density than even UltraVue though not as good as Artglass AR 70. The low iron glass base is the primary reason for the higher performance of Artglass AR 92. Overall I rate Groglass AR coatings as superior also.

The coating reflection color of Artglass AR 92 appears purplish (some batches may look bluish, some look more violet), when the specular reflection is from a light source striking the glass perpendicularly. The coating reflection’s hue becomes more intense if the light source emits proportionally more UV. At shallower reflection angles, the color shifts to blue, then green before graduating to neutral. It does not shift into opposing hues like Museum Glass or UltraVue. I have seen one anomalous sample from a batch where the coating color was blue, and it shifted to magenta before going to neutral.

Specular reflections appear brighter than the other three glasses. The UV reflecting coating has to throw back a small portion of the blue-violet portion in the visible spectrum. Over paper white, the glass appears yellowish, yet over dark areas, small amounts of glare can impart a bluish-purple color to the blacks. You can see this in the comparison images over black. The reflection color is just too far at the end of the visible spectrum to appear pleasant. A dull green or light sky-blue reflection color seems more acceptable to me.

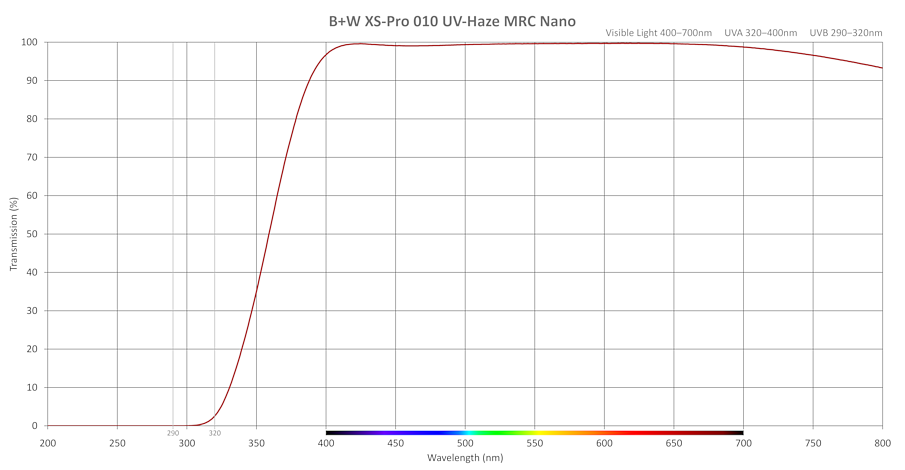

B+W XS-Pro UV-Haze MRC Nano filter

Just for kicks, here is the spectral transmission measurement from a B+W XS-Pro UV-Haze MRC Nano filter, one of the highest quality photographic lens screw-on filters available. Its performance is absolutely staggering and sets a benchmark for transparency. It does look a smidgen better than Artglass AR 70 in side by side comparisons over the black flocking material. But consider this—if the glass from this filter were available as a framing glass, it would be some 600 times the price of Artglass AR 70!

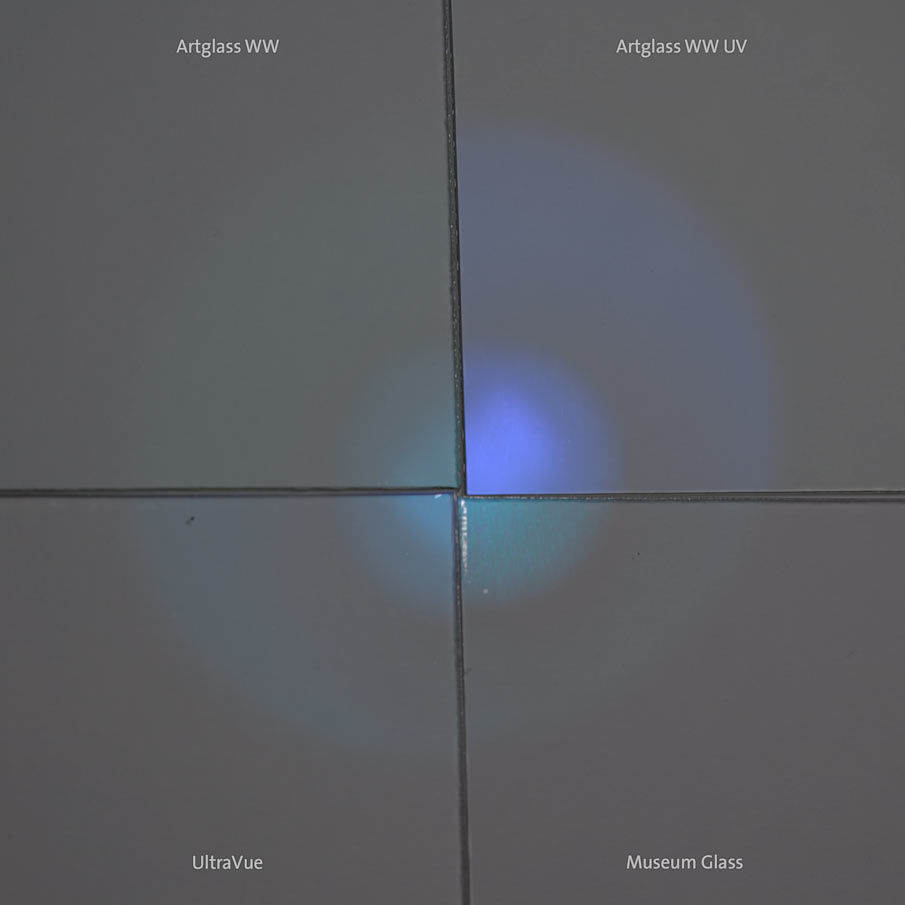

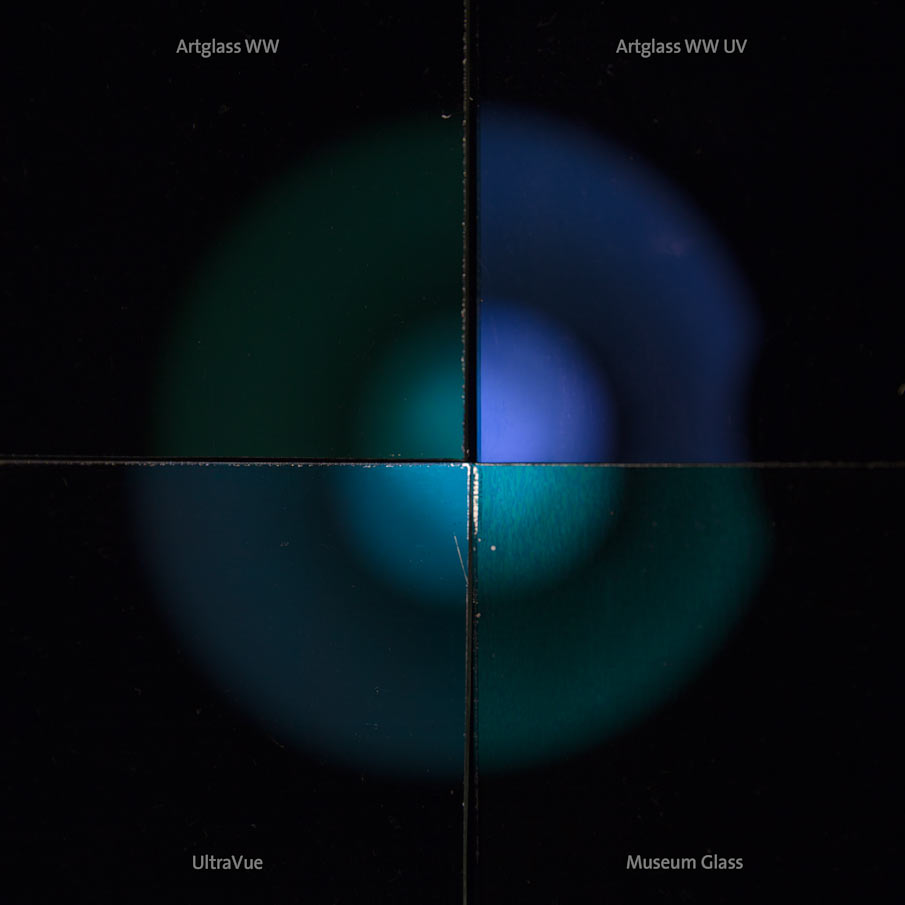

Tru Vue and Groglass AR Glasses Reflection Comparison

Finally we have two four-way comparisons showing a tungsten light reflection, where the illumination and viewing angles are more or less perpendicular to the glass surface. The glasses were placed over white paper that does not contain OBAs, and then again on a black flocking material. I have noticed when looking at these two images on several displays of varying quality, some calibrated, some not, Artglass AR 92’s reflection color may appear blue with no purple tint. The correct color should be blue with a hint of violet. Displays on mobile devices have gotten amazingly color accurate of late. If your mobile device uses one of those wider-than-sRGB OLED displays, remember to go into settings and change it to ‘standard’ or ‘photo’ screen mode or whatever the sRGB simulation setting is called, otherwise you will be looking at distorted colors all the time.

Note the extremely dull Artglass AR 70 reflection, brighter UltraVue and Museum Glass reflections and the brightest reflection from Artglass AR 92. Museum Glass’s wavy pattern is extremely obvious here!

Conclusion

My absolute favorite framing glass is Artglass AR 70. In every single way it meets or exceeds my expectations of what is possible, and at an affordable price. No it is not cheap like regular float glass, how could it be? But it most certainly is worth the price premium, especially considering the already substantial cost of custom framing. If not for the risk of shattering I would recommend it in every case where UV protection is not needed. To go from being almost unable to see anything clearly in a print due to surface glare and reflections, to being able to see almost everything, is why I consider AR glass to be one of the greatest leaps in visual quality to be had, in any part of the entire photographic imaging process.

When UV filtering is necessary, no AR coated glass on the market comes close to Museum Glass’s filtration effectiveness while offering such low levels of reflection. For the sake of maximum UV protection, one might overlook the shortcomings of this glass. But given its high cost, I cannot justify it for my own work, nor recommend it to my clients.

UPDATE: This is no longer the case. Groglass has since introduced Artglass AR 99, which is better than Museum Glass in several significant ways.

The ideal glazing for me would be anti-reflective, 99% UV blocking acrylic, which could be available in sizes much larger than glass, with good anti-static and abrasion resistance. For people who live in earthquake prone areas, or in the event of mishandling, or if to prevent accidental bodily harm, acrylic is much safer than glass. Tru Vue Optium Museum Acrylic (OMA) is currently the only product to fill this niche that ticks all the boxes. However, there is good news: Groglass has announced that they will make a similar product, and I am itching to find out how good it is.

Additional Thoughts

An AR-coated glass that is easy to handle, cut, clean and does not scratch easily is wonderful. Museum Glass is rather infamous for its soft, easily scratched UV coated side. This is an inconsequential detail to a customer paying for custom framing, but a potential nightmare for the framer. There are numerous stories on the web from frustrated framers raging about the difficulty of handling and cleaning Museum Glass and getting large pieces to be perfect. Of late, Tru Vue has gone to some lengths to make the coating on the UV side more durable. I am waiting for a sample of the new type to be sent to me to see just how much better they have made it.

Artglass AR 70/92 has no such issue. The coatings are extremely durable and can be treated with the same (lack of) care as regular glass. Less wastage means the savings may be passed on to the customer. After cleaning my samples several times for the comparison photographs, I find it easier to remove fingerprints from Artglass and I also experienced less scratching overall. One must still be careful. Once scratched, the coating is forever ruined and there is no method of repair, only replacement.

If the risk of shattering glass is a concern, there are laminated versions of Artglass and UltraVue, two 2mm water white sheets held together by a polyvinyl butyral resin, making a 4.4mm thick piece. There are versions that are even thicker. They all offer 99 — 100% UV filtering capability. But the significant weight and prohibitive cost would limit their use to only the most valuable artwork housed in specially reinforced frames or display cases and shops with specialised tools to cut this type of glass. Notably, glass is impervious to moisture, unlike acrylic, so this product can be useful in situations that require a hermetic seal but also cannot afford damage from shattering.

Acrylic (or commonly known by the brand name ‘Plexiglas’) is shatter-resistant and less than half the weight of glass for the same thickness. Its strength is similar to that of tempered glass but tends to break into large pieces rather than many tiny fragments. Clear acrylic is optically purer than low iron glass with essentially zero absorption of visible light. A big downside is that it scratches so effortlessly even mere dust picked up on a microfiber cloth will create ugly hairline swirls during routine cleaning. Acrylic is also more likely to hold a static charge making it unsuitable for framing flaky artwork like pastels. It can also attract a T-hinged fine art print and cause it to touch the acrylic, which may then stick to the glazing over time.

To overcome these problems with acrylic, anti-static and scratch-resistant coatings have been developed, and they work well in practice. OMA is currently the only picture framing product that embodies all these qualities. However I found it rather difficult to remove every last trace of fingerprints (or any oily smudges) on OMA. Rubbing too hard increases the risk of creating fine scratches which are then impossible to repair. To top it off, OMA is the most premium framing glazing, the cost can make your eyes water. This puts it out of reach for all but the most valuable artwork, collectors with deep pockets and museums with a good-sized budget for framing.

Acrylic is susceptible to warping or bowing if used in thin large sizes, owing to its lower mechanical strength than glass. 3mm acrylic is suitable for up to moderate sizes, anything large should use at least 4mm‒5mm acrylic. Acrylic sheets tend to come in much larger sizes than glass, making it possible to frame massive artwork without having to join two sheets together. Acrylic can absorb moisture and expand. If there is a significant humidity differential between the inside and outside of the frame, it will expand more on the wetter side.

Anyone concerned about the long term preservation of art is highly interested in the issues of UV light accelerating fading. Thanks to the Earth’s ozone layer, all of the UVC energy (<280 nm) is blocked. Regular glass blocks all of the UVB wavelengths (<315nm) and a fair amount of UVA energy, the 50% cutoff being 330nm. Plain acrylic blocks a little more UVA than glass with the 50% cutoff at about 360nm. Several products employ interference-based coatings that are claimed to be effective to filter out 90-92% of UV light. I consider these coatings to not be worthwhile. They lose their ability to block UV light at oblique angles and so are not effective enough in most real-world situations to warrant the significantly higher cost and the ugly brighter coating reflection colors. If UV filtering is needed, only consider UV absorbing coated glass like Groglass Artglass UV99 and Tru Vue Museum Glass. Otherwise, it is usually much better to just control the illumination of the artwork. Mark McCormick-Goodhart, director of Aardenburg Imaging & Archives, explained it beautifully and succinctly on the luminous-landscape forums:

“What many conservation professionals have failed to grasp over the years in this whole “UV is really damaging” argument is that ordinary window glass and even painted walls, carpeting, fabrics, etc (titanium dioxide used to make white paint is a strong UV absorber) already absorbs a very large percentage of UV energy entering homes and offices. Hence, art that is only indirectly illuminated by natural daylight scattered within an interior environment is already much reduced in the UV/Vis ratio compared to objects exposed outdoors to direct sunlight. Moreover, when indoor UV energy is at its highest ratio with respect to visible light, this condition also precisely correlates with sunlight coming through windows and directly striking the artwork!!!. Wherever that happens, overall light intensity is also incredibly high on the artwork, often up 1000x over other indirectly illuminated areas even in the same room. In these situations, full UV blocking glazing helps reduce fade rates at best 2-3x over plain glass, but it’s like rearranging the deck chairs on the Titanic. The absolute intensity associated with the direct sunlight goes up 100-1000x, and it is this peak intensity (UV filtered or not) that causes the primary damage to the artwork.

To put this argument in perspective, just 6 minutes average per day of sunlight streaming directly through a window onto a work of art will typically produce a 2x increase in average daily illumination (because the sunlight is so intense compared to indirect daylight conditions) and thus a 2x increase in fade rate on average. Moral of the story: Use UV blocking glazing if you want the absolute maximum amount of light fade protection, but pay even closer attention to where sunlight reaches actual surfaces in your home, even for just a few minutes per day on average. These are the locations, UV protected or not, where you are going to see faded art, faded upholstery, faded drapes, etc.”

The lifespan of art before noticeable fade or destruction occurs varies tremendously depending on several factors, including ambient temperature, humidity, atmospheric pollutants, outgassing and acids in presentation and storage materials, mold and insect attack etc. The environment as a whole needs to be considered when providing an ideal place to exhibit or store art. When exposed to sunlight, blue-violet visible light, while not as damaging as UV, is generally present in far greater proportions, making visible light the main contributor to light-induced fading. In tropical climates, the heat and humidity can destroy paper-based art 10-20X faster than exposure to normal amounts of illumination. It does not mean that UV filtration is unnecessary. In permanence testing, UV filtration can prolong the life of a typical inkjet print up to roughly two times compared to regular glass under bright white fluorescent lighting. The added protection may be worthwhile for anyone displaying their favorite art pieces where the lighting might be difficult to control, an important consideration for any artist providing general framing recommendations to their buyers. For museums and heritage institutions, ensuring that illumination on their exhibits are of ideally low intensity and contain no UV emissions is not difficult to achieve, and then simply having the most transparent framing glazing to present the art is just fine and dandy.

Samuel Chia

17 April 2015

References and Links

httpss://en.wikipedia.org/wiki/Anti-reflective_coating

httpss://en.wikipedia.org/wiki/Picture_framing_glass

httpss://aardenburg-imaging.com/index.html – the best known source of image permanence research

httpss://www.lensrentals.com/blog/2011/12/reflections-on-reflections-the-most-important-part-of-your-lens

httpss://www.thegrumble.com/index.php?threads/managing-the-transition-from-museum-to-artglass.72752/

Disclosure

I am not a representative or seller for any manufacturer or distributor of any of the above AR glass or acrylic products. I do not receive any remuneration for my recommendations. All my samples have been provided for free to me through the manufacturers’ own marketing program, through which anyone from anywhere can request for these complimentary samples too. I am not a custom framer nor do I sell any of these products through my own business. I pay fair market prices to my local framers for these glasses and for their custom framing products and services, and my choices are dictated by product performance and value, and also my clients’ requirements and preferences.

Revisions:

9 Sep 2015: Changed spectral graphs to include UV spectrum, revised article language.

9 Nov 2016: Revised article language. I have since received samples from the other manufacturers of AR glass, and am awaiting samples of newer products such as Artglass UV99 and the new “ripple-free” Museum Glass. Some of my conclusions and recommendations will be revised in light of the performance of these new and updated products in a future article.

2 Jul 2017: Revised article language.

5 Aug 2020: Updated product names to reflect manufacturer changes. The illustrations still retain the old naming conventions, so watch out!

23 Jul 2021: Revised article formatting and language.

One Comment

Comments are Disabled

[…] This is the second installment to “The Framing Glass” article, which delves into new 99% UV filtering anti-reflective (AR) glass and comparisons […]